Modifying your e-bike does not automatically void your entire warranty, but manufacturers are increasingly using software to enforce compliance.

- Proprietary CAN bus protocols now reject over 90% of aftermarket displays and controllers.

- Dealers use “frozen” diagnostic logs to prove modifications caused failure, shifting the burden of proof back to you.

Recommendation: Document every modification with timestamps and retain all original OEM parts to navigate the “Magnuson-Moss” protection effectively.

The desire to upgrade a fork for better damping or install a high-lumen headlight is natural for any enthusiast. You purchased the machine; logic dictates you should be able to improve it. However, for modders, the landscape of e-bike ownership has shifted from mechanical simplicity to a legal and digital minefield. It is no longer just about whether a part fits physically.

Common advice suggests simply “reading the manual” or asking your dealer, but this ignores the reality of modern proprietary ecosystems. From gem-set locking mechanisms to encrypted controller handshakes, the industry is building walls. The platitude that “minor mods are fine” is dangerous when a single error code can permanently flag your serial number in a cloud database.

But if we look closer, the real issue isn’t the modification itself, but the digital footprint it leaves. The angle often missed is that manufacturers are not voiding warranties based on the presence of a part, but on the data discrepancies that part creates. Understanding this distinction is the only way to successfully navigate the restrictions without losing your coverage. We will analyze the specific mechanisms manufacturers use to deny claims and how to legally insulate yourself.

This guide examines the intersection of technical constraints and consumer law to protect your investment. Here is the roadmap to understanding your rights.

Table of Contents: Navigating Warranty Restrictions

- Why “Universal” Parts Often Don’t Fit Proprietary E-Bikes

- Exceeding Weight Limits: What Manufacturers Say vs Reality

- Tapping into the Motor for Lights: Amp Limits You Must Know

- The Risk of “Tuning Chips” Being Detected by Dealer Software

- Reporting Issues Immediately: The Statute of Limitations on Defects

- Why a 2-Year Local Warranty Is Worth $500 More

- The Risk of DRMs Preventing Third-Party Battery Use

- Proprietary vs Standard Parts: The Right to Repair Your E-Bike

Why “Universal” Parts Often Don’t Fit Proprietary E-Bikes

The era of simple “plug and play” upgrades is rapidly ending due to the widespread adoption of Controller Area Network (CAN) bus systems. Unlike older UART setups where voltage was the primary language, CAN bus relies on encrypted digital handshakes between components. If the controller does not recognize the digital signature of a new display or throttle, the system simply refuses to operate.

This is not an accidental incompatibility; it is a design feature. Recent analysis reveals that Over 90% of 2024 Bafang motors use locked CAN bus systems that reject aftermarket displays. This digital lockout means that even if a connector physically fits, the firmware will prevent the flow of power. The ecosystem is closed to force the purchase of OEM components.

As noted by technical analysts regarding these protocols:

CAN BUS on conversion kits serves no purpose except locking you out of your own motor

– Voltriderz technical analysis, CAN-BUS vs UART Protocol Comparison

For the modder, this means research must shift from measuring diameters to verifying firmware versions. Investing in “universal” parts for a closed system is often a sunken cost from the moment of purchase.

Exceeding Weight Limits: What Manufacturers Say vs Reality

Structural integrity is the most common justification for warranty denial in frame failure cases. While motors are robust, the aluminum welds and suspension pivots have finite fatigue limits. When a rider modifies a bike to carry heavy cargo or adds heavy aftermarket batteries, they push the frame into an accelerated wear cycle that engineering teams can mathematically prove was outside design parameters.

Manufacturers are transparent about these limits, yet they are frequently ignored. Industry data indicates that most e-bikes support 220-300 lbs, with only specific cargo models rated for higher loads. Exceeding this, even by a small margin, creates micro-fractures in the heat-affected zones of welds.

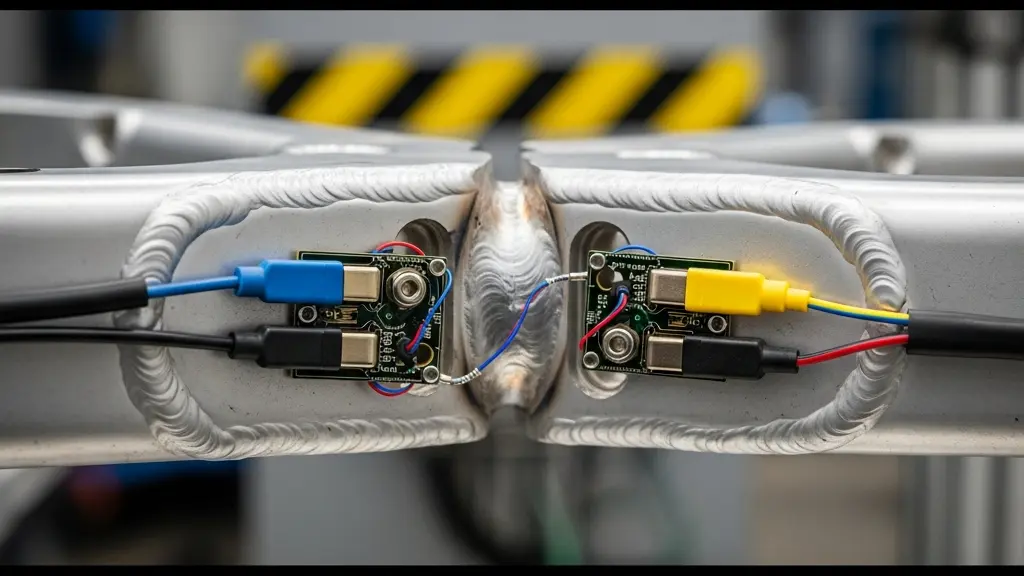

The visual evidence of this stress is subtle but definitive in a lab setting, as shown below.

As this stress testing setup demonstrates, manufacturers use strain gauges to map failure points. If a frame cracks and the forensic analysis shows stress consistent with overloading rather than a casting defect, the warranty claim is summarily denied. It is a matter of physics, not policy.

Tapping into the Motor for Lights: Amp Limits You Must Know

One of the most contentious areas of modification is the electrical system. Integrating high-power off-road lights by splicing into the main battery or controller leads is a frequent cause of system failure. From a legal standpoint, however, the burden of proof lies with the manufacturer to show that your specific modification caused the damage, rather than a pre-existing defect.

This protection comes from federal statutes. Under U.S. law, manufacturers must prove that the aftermarket part caused the failure to void the warranty. They cannot simply void it because you installed a light. However, if you draw more amps than the controller’s MOSFETs can handle and fry the board, that proof is easy for them to provide.

Plan of Action: Safe Electrical Modification

- Points of contact: Document your bike’s current state with dated photos before any modifications.

- Collecte: Create a modification log with receipts, installation dates, and component specifications.

- Cohérence: Send written pre-approval requests to manufacturers for specific modifications.

- Mémorabilité/émotion: Use only bolt-on accessories that don’t require splicing into main power lines.

- Plan d’intégration: Keep all original parts for potential warranty inspections.

By following a strict protocol of documentation, you create a paper trail that makes it difficult for a manufacturer to arbitrarily deny coverage based on the mere presence of aftermarket accessories.

The Risk of “Tuning Chips” Being Detected by Dealer Software

The installation of tuning chips to bypass speed limiters is the “nuclear option” for warranty voiding. Unlike physical parts, these chips interact directly with the bike’s logic board. Even if you remove the chip before a dealer visit, the bike’s internal history often retains the evidence. Modern controllers log peak RPM, max speed, and amp draw anomalies that are physically impossible without manipulation.

The “BESST” Detection Method

The BESST software for managing the configuration and firmware updates is an Electron app with all logic as plain HTML and JS files (and bundled source maps for all minified code), including the CAN frame specification. This architecture allows dealers to not only update firmware but to view a granular history of the bike’s performance. By analyzing timestamped data logs, technicians can identify periods where motor RPM exceeded the factory speed governor ratios, serving as irrefutable proof of tampering even after the tuning hardware is removed.

These “frozen” diagnostic logs act as a black box recorder. When a motor fails and the data shows it was spinning at 5000 RPM for extended periods, the warranty is voided instantly. There is no plausible deniability against the data log.

Reporting Issues Immediately: The Statute of Limitations on Defects

A critical, often overlooked aspect of warranty law is the timeline of reporting. Consumers frequently notice a minor issue—a noise or a vibration—and delay reporting it until it becomes a catastrophic failure. From a legal perspective, this delay can be interpreted as negligence, relieving the manufacturer of liability for the resulting damage.

Most warranties have strict clauses regarding the “discovery” of defects. For instance, Yamaha’s warranty policy specifically requires that defects must be reported within 10 days of discovery. If you continue to ride a bike with a known minor fault and that fault leads to a major motor failure a month later, you have technically violated the terms of the agreement.

This creates a “ticking clock” scenario. The moment you suspect a defect, the safest legal maneuver is to document it in writing to your dealer. This establishes a timestamp that protects you, proving that you acted responsibly to mitigate further damage.

Why a 2-Year Local Warranty Is Worth $500 More

When comparing direct-to-consumer e-bikes with dealer-supported models, the upfront cost difference is often attributed to branding. However, a significant portion of that premium funds the warranty reserve. A comprehensive warranty is not just a piece of paper; it is a service agreement that covers labor, which is often the most expensive part of a repair.

The disparity in coverage between budget and premium brands is stark, as detailed below.

As this comparison illustrates, premium coverage extends to the labor required to diagnose complex electrical faults, as seen in this warranty duration comparison.

| Warranty Type | Coverage Period | Components Covered | Industry Standard |

|---|---|---|---|

| Basic | 1 year | Motor, battery, controller | Most common (9/10 bikes) |

| Extended | 2 years | All electronics + frame | Premium brands |

| Comprehensive | 3-5 years | Full coverage including labor | Rare (Yamaha, EVELO) |

For a modder, a local warranty offers a tactical advantage: a human relationship. A local dealer may be more willing to overlook a minor cosmetic modification if they know you, whereas a faceless warranty department requires strict adherence to protocol. The premium price buys you an advocate.

The Risk of DRMs Preventing Third-Party Battery Use

The battery is the most expensive component of an e-bike, making it a prime target for aftermarket savings. However, Digital Rights Management (DRM) is increasingly used to bind batteries to specific bikes. This “battery marriage” involves the Battery Management System (BMS) communicating a unique serial key to the controller. If the keys do not match, the bike remains powered off.

This goes beyond simple compatibility. Manufacturers impose strict usage conditions to maintain warranty validity. For example, specific clauses state that battery warranty valid only if capacity remains above 50% after 700 charge cycles. Using a third-party charger or a non-OEM battery can disrupt the cycle counting logic of the BMS, potentially voiding the coverage for the entire electrical system.

The risk here is total system lockout. Modifying the BMS to accept a generic battery usually requires flashing the firmware, which we have established leaves a permanent digital scar. The short-term savings on a battery rarely outweigh the risk of voiding the warranty on the motor and controller.

Key Takeaways

- Modifications affect data logs, and data logs are what deny warranties.

- Timely reporting of defects (often within 10 days) is a legal requirement.

- CAN bus protocols create a digital “walled garden” that rejects universal parts.

Proprietary vs Standard Parts: The Right to Repair Your E-Bike

The conflict between aftermarket freedom and OEM control is effectively a battle for the Right to Repair. While proprietary parts ensure a controlled standard of safety and performance, they also create a monopoly on repair. Choosing a bike with standard parts (standard bearings, unconnected lighting systems, open-source displays) is the best defense against warranty headaches.

If you choose to modify a proprietary system, you are essentially betting against the house. The safety and longevity arguments from manufacturers are backed by data. Testing has shown that OEM parts often outlast generic alternatives because they are engineered as a system. The choice is yours: the freedom of open standards with higher maintenance responsibility, or the security of a closed ecosystem with strict rules.

Ultimately, the “void” warranty is often a self-inflicted wound caused by a lack of understanding of the digital systems at play. Knowledge of how the manufacturer tracks and validates your bike is your best tool for keeping it on the road.

Audit your current setup today: verify your warranty terms, document your modifications, and secure your investment before a technical issue becomes a legal one.

Frequently Asked Questions about E-Bike Warranties

Will exceeding weight limits void my warranty?

Most likely, yes. If component failure can be traced to exceeding the manufacturer’s weight specifications, warranty claims are typically denied. This is especially true for frame cracks, wheel damage, and brake system failures.

What are early warning signs of overloading?

Watch for spongy brakes, unusual frame flex or wobbling, new creaking sounds, suspension bottoming out frequently, and “pinging” sounds from spokes. These are warning signs that your bike is under excessive stress and needs immediate attention.

Can I safely exceed the limit by 10-15 pounds?

While you might not see immediate problems, being 10-15 pounds over puts you in the “accelerated wear” zone. This creates cumulative damage that may not be immediately visible.