An e-bike’s environmental credentials are not guaranteed by its purchase; they are earned through conscious choices regarding its battery, motor, and energy source.

- The largest environmental impacts stem from the manufacturing of the lithium-ion battery and the serviceability of the motor, not from electricity consumption.

- Comparing an e-bike to a shared e-scooter reveals that usage patterns and vehicle lifespan are more critical than per-kilometre emissions alone.

Recommendation: To genuinely minimize your carbon footprint, prioritize e-bikes with serviceable motors, charge with renewable energy where possible, and advocate for robust battery recycling programs.

The promise of the e-bike is compelling: a green, efficient, and healthy alternative to the automobile. Marketers are quick to point out the zero tailpipe emissions, positioning these vehicles as a panacea for urban pollution and climate change. For the eco-conscious consumer, however, a healthy skepticism is warranted. The narrative of a “green” product often conveniently overlooks the complex realities of its creation, use, and eventual disposal. Is your e-bike truly a climate champion, or does its environmental halo hide a more complicated truth?

The common discourse focuses on the obvious benefits, like saving on fuel and reducing traffic congestion. But this surface-level analysis fails to address the tougher questions that a sustainability analyst would ask. What is the embodied carbon in the aluminum frame and, more critically, in the energy-intensive lithium-ion battery? What happens to that battery at the end of its life? And does the design of the bike’s most crucial component—the motor—promote a long life of repair or a short path to the landfill?

This analysis moves beyond the simplistic car-versus-bike comparison. We will adopt a holistic ‘Lifecycle Carbon Accounting’ approach. The true environmental cost of an e-bike isn’t just about the electricity it consumes; it’s a comprehensive ledger that includes raw material extraction, manufacturing emissions, the carbon intensity of your local power grid, the durability of its components, and the effectiveness of its end-of-life recycling. The goal isn’t to discredit e-bikes, but to empower you with the data needed to understand that an e-bike’s green status is not a given—it’s a variable you can influence.

By dissecting each stage of the e-bike’s life, we will provide a clear, data-driven framework for calculating its real carbon offset. This guide will equip you to make informed decisions and transform your e-bike from a potentially “greenwashed” product into a genuinely sustainable mode of transport.

This article breaks down the complete lifecycle of an e-bike to provide a factual, nuanced perspective on its environmental impact. The following sections will guide you through the critical factors, from end-of-life challenges to daily operational costs and comparisons with other micro-mobility options.

Summary: A Comprehensive Lifecycle Carbon Analysis for E-Bikes

- Why Recycling Lithium Batteries Is Still a Logistical Nightmare

- How to Charge Your E-Bike with Solar Power at Home

- E-Bike or Electric Scooter: Which Has the Lower Lifetime Emission?

- The Mistake of Buying Non-Serviceable Motors That Creates E-Waste

- Refurbish or Replace: Extending Motor Life Beyond 5 Years

- Why Electricity Costs Less Than $5 Per Year for Daily Commuters

- How to Claim E-Bike Rebates for Your Small Business

- The Real Cost of E-Biking: Depreciation, Electricity, and Maintenance

Why Recycling Lithium Batteries Is Still a Logistical Nightmare

The single most significant component in an e-bike’s environmental footprint is its lithium-ion battery. While their operational life is clean, their end-of-life (EoL) presents a formidable challenge. The primary obstacle is not technology but logistics and economics. The good news is that advanced hydrometallurgical processes are highly effective; for instance, some new facilities boast a recovery rate exceeding 96% for critical materials like lithium, nickel, and cobalt. The problem lies in getting a sufficient volume of spent batteries to these facilities to make the process economically viable.

Paradoxically, a key barrier is the improving longevity of the batteries themselves. Batteries in electric vehicles and e-bikes are lasting longer than initially projected, meaning there is surprisingly little “dead” material on the market to create a steady stream for recyclers. Furthermore, the collection infrastructure is deeply inadequate. Establishing consistent and safe collection networks is a complex undertaking, hindered by varying regulations across regions and the inherent fire hazards associated with transporting damaged lithium-ion batteries. Programs like the Call2Recycle initiative, endorsed by PeopleForBikes, are making progress by coordinating disposal for dozens of e-bike brands, but scaling these efforts globally remains a huge hurdle.

The economic landscape adds another layer of complexity. The global refining capacity for key materials is highly concentrated, with over 70% of the world’s cobalt refining, for example, done in China. This creates volatile supply chains and pricing. When the cost of virgin materials is low, the economic incentive to recycle diminishes. This dynamic makes it difficult for recycling businesses to secure long-term profitability, creating a classic chicken-and-egg problem: without a consistent supply of old batteries, large-scale recycling plants are not built, and without these plants, there is no efficient place to send the batteries.

How to Charge Your E-Bike with Solar Power at Home

While the embodied carbon of an e-bike is significant, you have direct control over the emissions from its daily use. The “greenness” of charging your bike depends entirely on the carbon intensity of your local electricity grid. To truly achieve zero-emission commuting, you can decouple from the grid entirely by setting up a home solar charging system. This is more accessible than many assume and ensures every mile you ride is powered by renewable energy.

A basic DIY setup involves three core components: a solar panel, a charge controller, and the necessary wiring. The key is selecting the right charge controller, specifically an MPPT (Maximum Power Point Tracking) boost solar charge controller designed for your battery’s specific chemistry (lithium-ion) and voltage (e.g., 36V or 48V). Brands like Genasun offer models pre-configured for common e-bike battery voltages. For the panel itself, flexible panels using high-efficiency SunPower solar cells are a great option if you need portability, while rigid panels offer more wattage for the price in a stationary setup.

The time required to charge is a direct function of the panel’s wattage and sunlight conditions. You are not limited to a slow trickle charge. A powerful-enough system can be highly practical for daily use. For example, field testing shows it takes about 6-7 hours to fully charge a 14Ah e-bike battery using a 160W foldable solar panel. This means you can easily charge your bike during the workday for the commute home. In contrast, a smaller 60W panel could take up to 16 hours, making it more suitable for overnight or weekend charging. By investing in a capable solar setup, you take full ownership of your e-bike’s energy supply, transforming it into a truly carbon-free vehicle.

E-Bike or Electric Scooter: Which Has the Lower Lifetime Emission?

When evaluating micro-mobility options, a direct comparison between an e-bike and an electric scooter reveals that lifecycle emissions are about much more than just the energy used per kilometre. From a holistic, lifecycle perspective, the e-bike consistently demonstrates a lower carbon footprint, primarily due to differences in manufacturing, lifespan, and typical use cases. The shared e-scooter model, in particular, suffers from significant hidden environmental costs.

The most glaring difference is in the vehicles’ lifespan. A privately owned e-bike is typically treated as a valuable asset, well-maintained, and can last for 20,000 km or more. Shared e-scooters, conversely, are subjected to heavy use, abuse, and vandalism, leading to a much shorter operational life before they become e-waste. This high turnover rate means the embodied carbon from manufacturing is amortized over far fewer kilometres. Furthermore, the shared model requires a fleet of fossil-fueled vehicles to collect, rebalance, and charge the scooters, adding a significant layer of operational emissions that privately owned e-bikes do not have. This is a critical factor often overlooked in simple emissions-per-kilometre calculations.

The following table, based on lifecycle analysis principles, breaks down the key factors. It highlights how the manufacturing and operational model of shared e-scooters results in a higher overall environmental burden compared to a personally owned e-bike. A recent comparative analysis from academic sources underpins these findings.

| Factor | E-Bike | E-Scooter (Shared) |

|---|---|---|

| Manufacturing CO2e | 134kg | Higher due to fleet turnover |

| Emissions per km | 13g CO2e/km | Higher with rebalancing needs |

| Typical Lifespan | 20,000km | Much shorter (vandalism/abuse) |

| Modal Replacement | Often replaces car trips | Often replaces walking/transit |

| Recyclability | 95% battery recovery possible | Often complete e-waste |

Finally, the concept of modal replacement is crucial. Studies show that e-bike trips often replace journeys that would have otherwise been made by car, leading to a direct and significant carbon offset. E-scooters, on the other hand, more frequently replace walking or public transit trips, resulting in a net increase in emissions for that journey. Therefore, while both are better than a car, the e-bike provides a more substantial net benefit in decarbonizing urban transport.

The Mistake of Buying Non-Serviceable Motors That Creates E-Waste

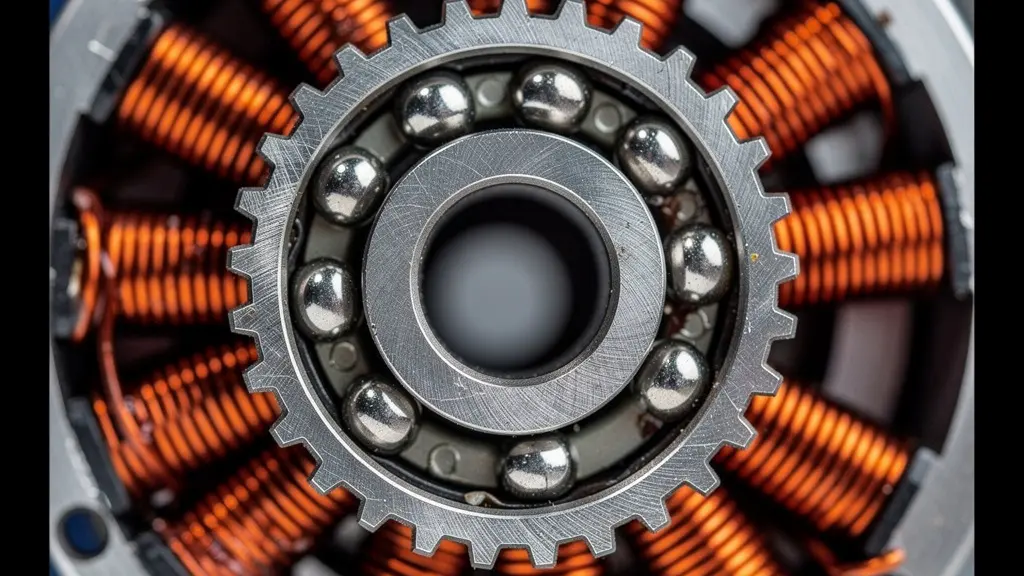

Beyond the battery, the electric motor is the heart of an e-bike and a significant source of potential e-waste. A common, and costly, mistake consumers make is purchasing a bike with a non-serviceable motor. Many major brands design their motor units as sealed “black boxes,” effectively preventing independent repair and forcing a full replacement for even minor issues like a worn-out bearing. This business model of enforced disposability dramatically shortens the useful life of the entire drive unit and contributes directly to the growing problem of electronic waste.

This design philosophy is often presented as a feature, ensuring quality and water resistance. As the technical documentation from one major service center notes regarding a popular brand:

Bosch motors are not designed to be serviced and should only fixed if they start to fail. The motors are sealed for life and if kept dry will do in excess of 50,000 miles (80,000km) without problem

– eBike Motor Centre, Technical FAQ Documentation

While a long potential lifespan is promised, the “sealed for life” approach means that if a simple component fails prematurely, the entire costly motor must be discarded. In contrast, serviceable motors allow for the replacement of individual wear-and-tear components like bearings, seals, and gears, extending the motor’s life indefinitely for a fraction of the cost of a new unit. Choosing a bike with a serviceable motor is one of the most impactful decisions you can make to reduce its long-term environmental footprint and overall cost of ownership.

Before purchasing an e-bike, it’s essential to investigate the serviceability of its motor. This small bit of research can save you thousands of dollars and prevent unnecessary waste down the line.

Action Plan: How to Identify a Serviceable E-Bike Motor

- Check Motor Housing: Look for visible bolts or seams on the motor casing. Perfectly smooth, sealed units are a red flag for non-serviceability.

- Research Spare Parts Availability: Search online for your specific motor brand and model plus terms like “bearings,” “seals,” or “spare parts.” If only complete motor units are for sale, it’s likely non-serviceable.

- Inquire About Bearing Replacement: Ask the retailer or manufacturer directly: “Can the bearings in this motor be replaced by an independent mechanic?” A vague or “no” answer is telling.

- Verify Diagnostic Software Access: Check if independent shops can access the motor’s diagnostic software. Proprietary systems that lock out third-party repairs are a major indicator of a closed ecosystem.

- Assess Firmware Update Policies: Determine if firmware updates can be performed by the owner or require a dealer visit. Software-locked components can force premature replacement of otherwise functional hardware.

Refurbish or Replace: Extending Motor Life Beyond 5 Years

The logical and sustainable alternative to replacing a non-serviceable motor is to embrace a culture of repair and refurbishment. For e-bikes equipped with serviceable motors, a proactive maintenance schedule can extend the unit’s life far beyond the typical 5-year warranty period, often indefinitely. This approach not only prevents e-waste but is also significantly more cost-effective, turning a potential multi-thousand-dollar replacement into a few-hundred-dollar service.

Professional e-bike motor repair services offer comprehensive packages that go far beyond a simple wipe-down. A “regular” service typically includes a full strip-down of the motor, cleaning of all internal components, inspection for wear, and reassembly with high-quality grease. This process helps prevent the most common cause of motor failure: water and grit ingress. By cleaning and re-greasing seals and bearings periodically, you maintain the motor’s internal integrity and ensure it runs smoothly and efficiently for years to come. This preventative maintenance is the key to longevity.

For motors that are already showing signs of wear, such as grinding noises or play in the axle, a full refurbishment is the solution. This involves a complete tear-down and replacement of every bearing within the motor. Specialists use high-quality bearings, often exceeding the original manufacturer’s specifications, along with manufacturer-recommended grease to restore the motor to a like-new condition. By investing in the serviceability and refurbishment of your motor, you fundamentally shift its lifecycle from a linear path (manufacture -> use -> discard) to a circular one (manufacture -> use -> service -> use -> service), which is the cornerstone of a truly sustainable ownership model.

Why Electricity Costs Less Than $5 Per Year for Daily Commuters

A frequent point of discussion for prospective e-bike owners is the cost of charging. While it seems intuitive that plugging in a vehicle every day would lead to a noticeable increase in electricity bills, the reality is that e-bikes are astonishingly efficient. For a typical daily commuter, the annual cost of electricity is not just low—it’s often negligible, amounting to less than the price of a few cups of coffee. This economic advantage further strengthens the case for e-bikes over fossil-fueled transportation.

The math is straightforward and compelling. E-bikes consume a very small amount of energy per mile. In fact, real-world testing demonstrates that most can easily travel 100 miles (160 km) on just one dollar’s worth of residential electricity. When you extrapolate this over a year of daily commuting, the total cost remains incredibly low. The efficiency of the motor and battery system means that you are getting a massive amount of transportation for a minimal energy input. This hyper-efficiency is what separates e-bikes from larger electric vehicles like cars, whose larger batteries and weight require significantly more power.

Let’s break down a typical scenario. The following table illustrates the annual electricity cost for a rider with a 10-mile daily commute, using a standard 500Wh battery and an average US electricity price. As the calculation shows, the total yearly expenditure is remarkably small, often landing under five dollars.

| Parameter | Value | Annual Impact |

|---|---|---|

| Battery Capacity | 500Wh typical | – |

| Charge Efficiency | Approx. 93% | – |

| Daily Commute | 10 miles | 2,600 miles/year |

| Energy per Mile | 10-15 Wh | 26-39 kWh total |

| Cost at $0.12/kWh | $0.0012-0.0018/mile | $3.12-4.68/year |

This minimal operational cost is a powerful financial incentive. It underscores a key point in the e-bike’s lifecycle analysis: the primary costs, both financial and environmental, are front-loaded in the manufacturing and purchase price. The ongoing running costs are, for all practical purposes, close to zero, freeing up resources that can be better spent on proper maintenance to extend the vehicle’s life.

How to Claim E-Bike Rebates for Your Small Business

Beyond personal commuting, e-bikes offer a powerful tool for small businesses looking to reduce operational costs and their carbon footprint. Many governments at the federal, state, and local levels recognize this and offer financial incentives, such as rebates and tax credits, to encourage commercial adoption. For a small business, using e-bikes for deliveries, client visits, or general errands can be made even more affordable by strategically leveraging these programs.

Navigating these incentives requires careful planning. The first step is to thoroughly research all available programs in your specific area, as funding and eligibility requirements can vary significantly. Some programs offer a point-of-sale discount, while others provide a cash rebate after purchase. It’s crucial to differentiate between a rebate (immediate cash back) and a tax credit (which reduces your tax liability later). For tax purposes, maintaining a detailed mileage log to document business use is essential. This allows you to legally depreciate the e-bike as business equipment over its useful life, providing an additional financial benefit.

To maximize the return on investment, businesses should think holistically. The calculation should include not only the direct savings from the rebate and fuel costs but also secondary benefits. These can include savings on vehicle parking, reduced maintenance costs compared to a car, and even improved employee wellness and productivity. Because many of these programs operate on a first-come, first-served basis with limited annual funding, it is vital to apply as early as possible once you have made a purchasing decision. Proactive planning is key to successfully securing these valuable incentives.

Key takeaways

- An e-bike’s true environmental impact is determined by its entire lifecycle, not just its zero tailpipe emissions.

- The manufacturing of the battery and the serviceability of the motor are the two most critical factors in its long-term carbon footprint.

- You can actively reduce your e-bike’s impact by choosing to charge with renewable energy and prioritizing models built for repair, not disposal.

The Real Cost of E-Biking: Depreciation, Electricity, and Maintenance

To perform a true carbon offset calculation, we must look at the complete picture of ownership costs, both financial and environmental. The “real cost” of e-biking is a composite of three main factors: the purchase price and its depreciation, the minimal cost of electricity, and the crucial, often underestimated, cost of maintenance. As we’ve seen, electricity is a negligible expense. The real variables that determine the total cost of ownership—and its environmental parallel—are the upfront investment and the commitment to long-term care.

Depreciation is the largest single financial cost. An e-bike, like any vehicle, loses value over time. However, this financial loss is directly linked to an environmental principle: the longer you use the bike, the more its initial embodied carbon is amortized over a greater number of miles, reducing its per-mile footprint. This is where maintenance becomes the most critical lever. Investing in regular servicing, bearing replacements, and keeping the drivetrain clean doesn’t just save money on costly repairs; it extends the bike’s lifespan, directly improving its carbon ROI. A well-maintained, serviceable e-bike that lasts 10 years has a dramatically lower lifecycle footprint than a neglected one that is discarded after three.

Finally, a truly comprehensive analysis must even account for the cyclist. A fascinating piece of research from the BikeRadar team found that for conventional cycling, over 75% of its carbon footprint comes from the extra food the cyclist consumes to power the ride. While an e-bike’s motor assist reduces this caloric need, it doesn’t eliminate it. This highlights the complexity of true lifecycle accounting; every input, from battery minerals to the rider’s breakfast, has a carbon cost. It reinforces our central theme: the greenest e-bike is one that is used for a long time, replaces car trips, is maintained meticulously, and is powered, as much as possible, by renewable energy.

To truly validate the environmental impact of your e-bike, move beyond marketing claims by adopting a lifecycle perspective. Prioritize durability and serviceability at the point of purchase, commit to a robust maintenance schedule, and evaluate your charging habits. This analytical approach is the only way to ensure your investment delivers a genuine carbon offset.

Frequently Asked Questions on Is Your E-Bike Really Green? Calculating the Carbon Offset vs Cars

What documentation is typically required for business e-bike rebates?

Most programs require proof of purchase, business registration certificate, tax ID number, and a statement of intended business use.

Can e-bikes be claimed as business tax deductions?

Yes, e-bikes used for business purposes can typically be depreciated as business equipment over their useful life.

What’s the difference between a rebate and a tax credit?

Rebates provide immediate cash back after purchase, while tax credits reduce your tax liability during filing.